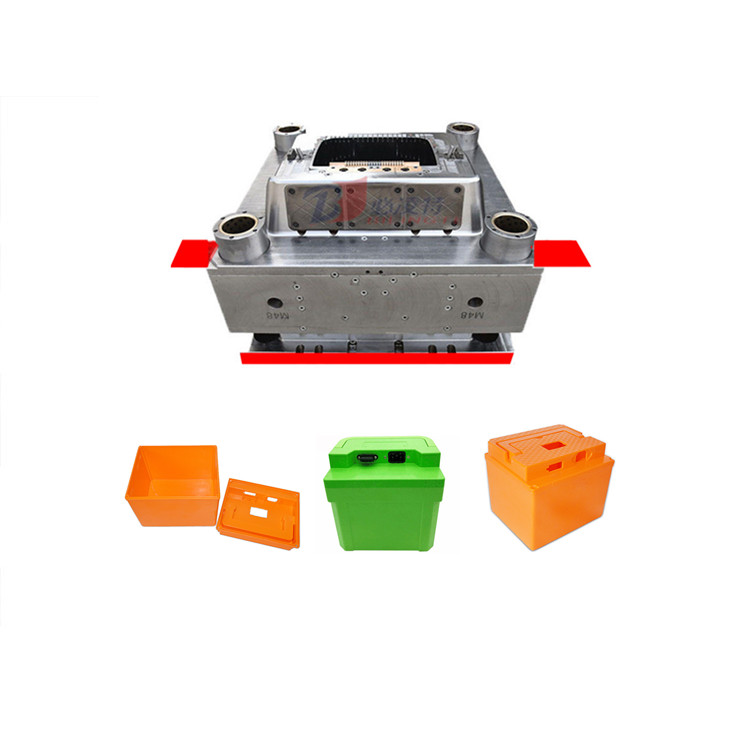

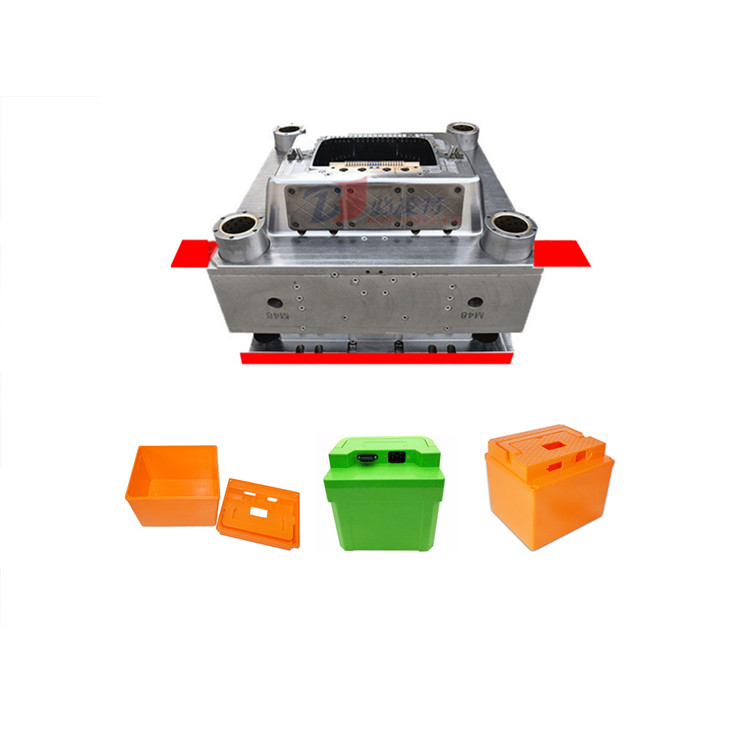

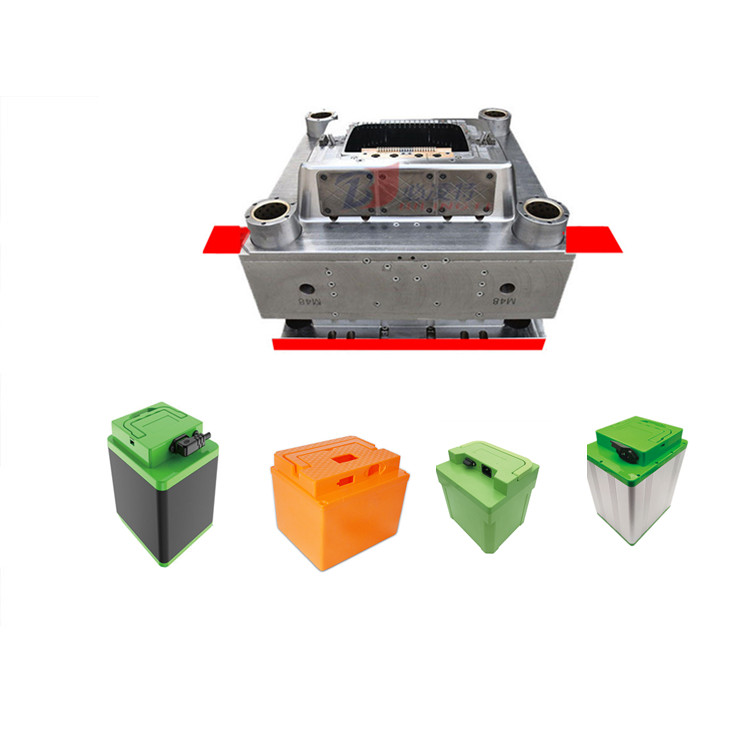

Battery Box Plastic Mold Main Feature

gas stove battery box mould

1. Multi-cavity battery box mold design and tooling abilty

2. High speed injection cycle time

3. Fast & optimal cooling system design for battery box mold

4. Moldmax material application in gas stove battery box mould core & cavity

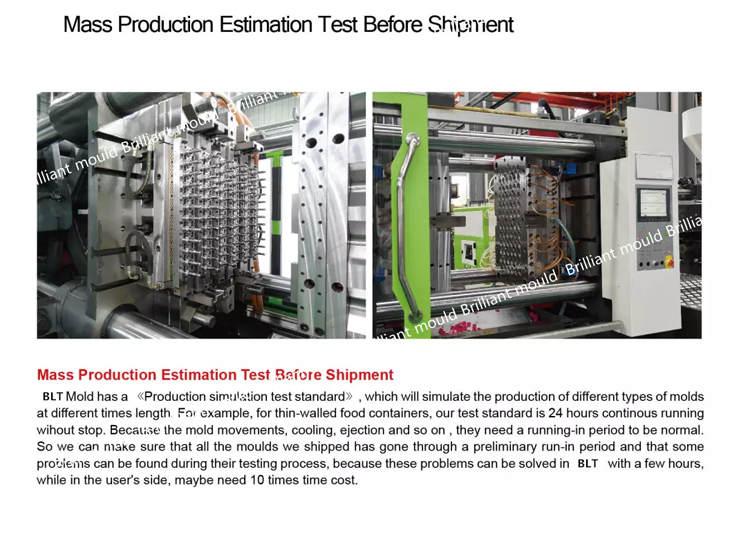

Precision Tooling Equipment

All of battery box plastic mold parts are manufactured by CNC equipments. Independent

cooling system of each cavity to ensure the size consistency, temperature-control box

included, Standard interchangeable mold components, Send samples to customers for

inspection. Our workers are fully qualified and skilled at using modern production techniques.

Computerized CNC (Computer Numeric Coordinates) Systems (CAD/CAM) produce newmolds

with money-saving speed and accuracy. We employ a wide range of manual, automatic

and computerized equipment in making moulds.

About Us

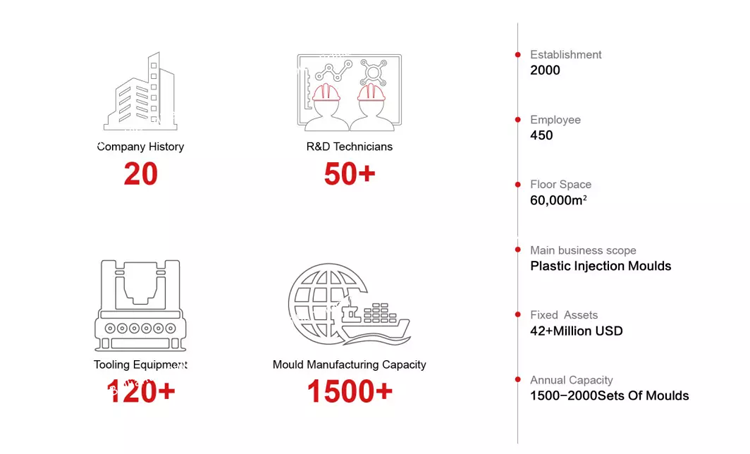

Brilliant Mould was established in 2003. It has 16 years of plastic molds experience and more than

10 years of foreign trade experience. Brilliant Mould is engaged in the production and sales of

plastic moulds, so it fully accepts OEM services. Support sample customization, we have our own

factory and trading department, as well as R & D department and quality control department.

Currently, we have exported a variety of plastic moulds to 70 countries, such as the United States,

Canada, Poland, Colombia, Belarus, Chile, Mexico, Turkey, Saudi Arabia, Egypt, etc. Thanks customers

for their long-term cooperation and recognition of our good service attitude, and looking forward

that we can establish a long-term cooperative relationship.

Battery Box Mould Produce Process

1. Design 2D 3D battery boxs' drawings and confirm with customers;

2. Design 2D 3D battery box molds' drawings and confirm with customers;

3. Produce battery box mold;

4. Write the mold production progress report to customers every week;

5. The mold production is completed and will make the first mold trial;

6. If there is no problem with the product, mail the battery box sample to the customer for confirmation;

7. If there is the problem with the product, repair the mold and make mold trial again;

8. Mail the sample to the customer, and the customer confirms the sample;

9. Deliver battery box mold.

FAQ

1.Q:Are you a factory or trading company?

A: Factory.

2.Q:What type molds you can make?

A:We can make all kinds of plastic injection molds, but we are very good at the production

of packaging molds such as battery box mold.

3.Q:Can you make the specific molds according to customers?

A:Yes.

4.Q:Can you print customers’ logo?

A:Yes.

5.Q: What is the mold design software??

A: CAD,UG etc.

6.Q: How long is your delivery time?

A: Generally it is 45-65 days.

7.Q: Do you provide samples ?

A: Yes, We will provide samples to our customers after the first molds trial by free.

8.Q:How to ensure the quality of the product?

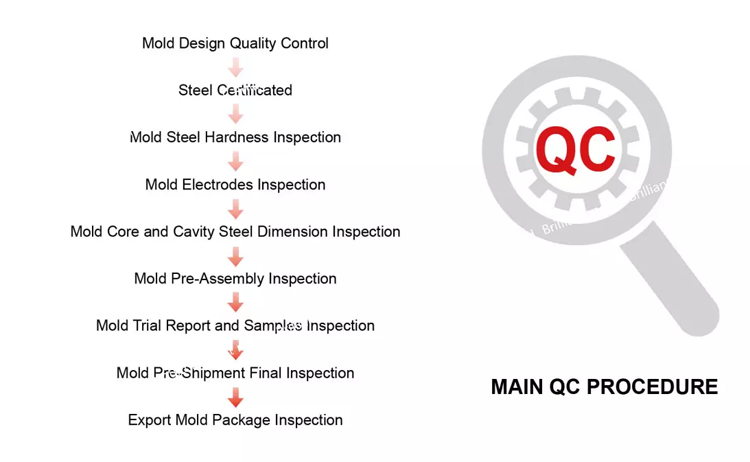

A:We have great R & D department and strict quality control department. We will design and

manufacture all kinds of molds according to customer's requirements.

Contact Us

Tel/Whatsapp/Wechat: +8618534991705

Email: brilliant-mould@hotmail.com info@brilliantgroupe.com

Current Location:

Current Location: